Octane Gasoline

Improve your profitability and increase the blend quality of your gasoline

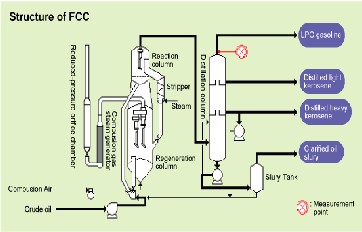

The API process catalytically combines light olefins such as propylene, butylene or amylene with isobutane to increase their value and make an environmentally sound our product for high-octane gasoline blending.

API technology offers:

- Production with a low RVP and near-zero olefin and aromatic content

- Acid consumption more than 200 times lower per barrel of compared to other direct technologies for lower overall operating costs reduced acid handling

- Enhanced process operation to reduce acid volatility and improve overall plant safety through the process

Additionally, API offers an indirect process that improves gasoline blend quality by producing a clean-burning, mid-boiling-range iso-paraffin, which is a high octane, low RVP, low sulfur with no olefins or aromatics blend component. The API process uses standard hydrocarbon processing technology and catalysts, offering the flexibility to meet your operation’s objectives.

Isobutane Production

For the production of isobutane, a primary feedstock for the our process, the API process is a highly efficient and low-cost solution. With the increased penetration of ethanol into the overall gasoline blend pool, there will be an increased need for our and, as a result, a focus on economic in situ routes for producing isobutane to feed the our process. A continuous development program aimed at improving the design, operating, and catalyst employed in this process has positioned this process to meet the future needs of gasoline focused refiners.